Episode

“Japan’s First” in the Construction of the Lake Biwa Canal

A major civil engineering project conducted by Japanese engineers

In Japan, in the Meiji Era (1868-1912), it was common practice to use engineers from outside Japan to design and supervise civil engineering works. The Lake Biwa Canal construction was the first large-scale modern civil engineering project that was completed by Japanese workers alone, from surveying, designing to execution. The project was directed by Sakuro Tanabe, an engineer who had studied modern civil engineering technology. There was no heavy machinery readily available at that time, and most of the work was accomplished by manual labor. In addition, the bricks used in constructing the canal all came from a brick factory built specifically for that purpose.

![Lantern [Provided by the Tanabe Family]](/shared/tsumiki/a9127544016ecab599f053b8b80bf1a6.jpg)

Lanterns, or portable lamps were used to work in the dark tunnels because electric lamps were not available.

Lanterns were made of iron, and the top edge of a lantern could be hooked over rocks to secure it in position.

“Illustrations of the Lake Biwa Canal Construction” (by Soryu Tamura)

Clay used to make the bricks was gathered from nearby areas. The number of chimney stacks increased to eight later.

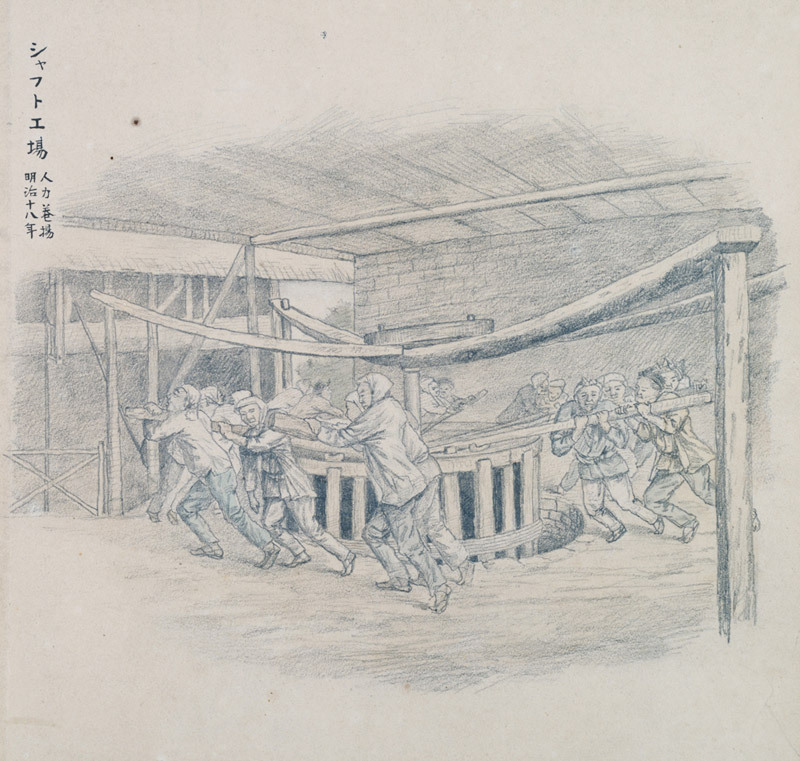

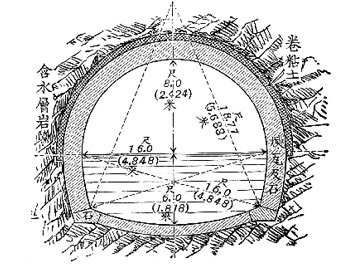

First attempt at tunnel construction

Sakuro Tanabe adopted an excavation method that utilized shafts for the construction of the First Tunnel, the Japan’s longest tunnel at the time. This was a technique used in mining, and it was employed for the first time in Japan for tunnel construction. A shaft was drilled straight down from the mountain top to the depth where the tunnel was planned to be built, so that tunnel was bored simultaneously from both outside and inside the mountain. This technique shortened the construction time. Another shaft was drilled for lighting and air ventilation. The depth of the First Shaft is about 47 meters. Scaffolding was erected at certain points, and workers and materials were carried up and down using a manual hoisting winch installed at the top of the shaft. You can see the inside of the shaft as you pass under it on the Lake Biwa Canal Cruise.

“Illustrations of the Lake Biwa Canal Construction” (by Soryu Tamura)

Works done at the top of the shaft, at the beginning of excavation.

A large manual hoisting winch was used to carry workers up/down the shaft and to bring water out of the tunnel. They had to work all day and all night if there was a lot of flooding groundwater.

Establishment of Japan’s first hydroelectric power plant for industry

In the 19th century, electric power was put into practical use as a new energy source worldwide. Sakuro Tanabe and Bumpei Takagi went to the US to observe the use of hydroelectric power. Greatly inspired by a hydroelectric power plant in Aspen, Colorado, Tanabe became convinced of the practicality and possibilities of this type of electric power. On returning to Japan, Tanabe and Takagi proposed construction of a power plant in the Lake Biwa Canal project, and hydroelectric power was added as a reason for utilization of the canal. Japan’s first hydroelectric power plant for industry, Keage Power Plant (first construction period), was established in 1891.

![Inside the Keage Power Plant built during the first construction period (About 1897)

<br>[Provided by the Tanabe Family]](/shared/tsumiki/3f4301b8c56595520a4e537ecf1f1280.jpg)

[Provided by the Tanabe Family]

Waterworks system utilizing Japan’s first rapid sand filtration method

Keage Filtration Plant started its water supply service in 1912: The beginning of the waterworks history of Kyoto. A method referred to as “rapid sand filtration” was employed at this filtration plant. This is a method utilizing chemical reactions to cause particles to form in the water which can then be filtered out, efficiently purifying the flow. This is a method commonly used today, and the Keage Filtration Plant employed the method for the first time in Japan. The filtration plant adopted the method because it was built on the side of Mt. Kacho, and accordingly did not have enough space for a large filter basin required for slow sand filtration. When the filtration plant was established, the plant could supply water to only about 40,000 people in Kyoto City, out of total population of about 500,000, and the maximum supply amount per a day was about 30,000 cubic meters. Today, the plant supplies more than 500,000 cubic meters of water per day, assuring a safe and secure water supply to support people’s lives.

Source: “The Three Major Projects of Kyoto City”

“Japan’s first ferro-concrete bridge”

Hinooka No.11 Bridge stands on the east side of the Third Tunnel of the First Canal. The bridge looks nondescript, but it is Japan’s early ferro-concrete bridge. It was built in 1903 under the direction of Sakuro Tanabe. Engraved on the stone monument by the bridge is “Japan’s first ferro-concrete bridge.” Not many ferro-concrete bridges built in the Meiji Era still exist nationwide today. Therefore, the Hinooka No.11 Bridge is an extremely valuable cultural asset in the field of technical history.

“Pocket Book of Engineering Formulae”

“Pocket Book of Engineering Formulae” (Japanese: Shuchin Koshiki Koshi Hikkei) is Japan’s first handbook for civil engineering composed by Sakuro Tanabe. Most of the engineers involved in the Lake Biwa Canal construction, who came from all around the nation, had very little knowledge about new civil engineering construction techniques brought in from Western countries. Therefore, Tanabe himself lectured the engineers on civil engineering technologies in the evenings, while spearheading the construction during daytime. The “Pocket Book of Engineering Formulae” is a compilation of the materials he used to train the engineers at that time. In the book, Tanabe described basic techniques used in civil engineering, including formulae required for surveying, and preservation methods for gunpowder. It is a pocket-sized book that engineers can carry around with them while on the job.

![“Pocket Book of Engineering Formulae”

<br>(5th edition) [Provided by the Tanabe Family]

<br>Written by: Sakuro Tanabe

<br>Published: February 20, 1897](/shared/tsumiki/2b3a38f391ba27fa347f1cf5a30c22bb.jpg)

(5th edition) [Provided by the Tanabe Family]

Written by: Sakuro Tanabe

Published: February 20, 1897